|

|

|

|

|

|

| Heat treatment Basket - Heat resistant steel casting |

Heat treatment Basket - Heat resistant steel casting |

Heat treatment Basket - Heat resistant steel casting1 |

Heat treatment Basket - Heat resistant steel casting |

Heat treatment Basket - Heat resistant steel casting |

Heat treatment Basket - Heat resistant steel casting |

|

|

|

|

|

|

| Heat treatment Basket - Heat resistant steel casting |

Heat treatment Basket - Heat resistant steel casting |

Heat treatment Basket - Heat resistant steel casting |

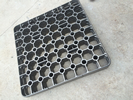

Heat treatment Base Tray - Heat resistant steel casting |

Heat treatment Base Tray - Heat resistant steel casting |

Heat treatment Base Tray - Heat resistant steel casting |

|

|

|

|

|

|

| Heat treatment Base Tray - Heat resistant steel casting |

Heat treatment Base Tray - Heat resistant steel casting |

Heat treatment Base Tray - Heat resistant steel casting |

Heat treatment Base Tray - Heat resistant steel casting |

Heat treatment Base Tray - Heat resistant steel casting |

Heat treatment Base Tray - Heat resistant steel casting |

|

|

|

|

|

|

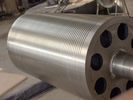

| Funace Roller - Heat resistant alloy casting |

Funace Roller - Heat resistant alloy casting |

Funace Roller - Heat resistant alloy casting |

Funace Roller - Heat resistant alloy casting |

Funace Roller - Heat resistant alloy casting |

Funace Roller - Heat resistant alloy casting |

|

|

|

|

|

|

| Radiant Tube I Type - Heat resistant alloy casting |

Radiant Tube I Type - Heat resistant alloy casting |

Radiant Tube I Type - Heat resistant alloy casting |

Radiant Tube U Type - Heat resistant alloy casting |

Radiant Tube U Type - Heat resistant alloy casting |

Radiant Tube W Type - Heat resistant alloy casting |

|

|

|

|

|

|

| Sink Roller - Heat resistant alloy casting |

Sink Roller - Heat resistant alloy casting |

Heat treatment Product - Heat resistant alloy casting |

Wax Injection for Lost Wax Casting |

Mold Dring for Lost Wax Casting |

Mold for Lost Wax Casting |

|

|

|

|

|

|

| Electrical Furnace for Lost Wax Casting |

Spectrum Analyzer for Lost Wax Casting |

Melt Pouring for Lost Wax Casting |

Shot Blast Machine for Lost Wax Casting |

Shot Blast Machine for Lost Wax Casting |

Shot Blast Machine for Lost Wax Casting |